Analysis of disassembly, maintenance and alignment of clamped coupling

Release time:2019-02-21

Release time:2019-02-21Coupling finding is one of the most important tasks in machine installation. The purpose of alignment is to make the center line of the driving shaft and driven shaft in the same line when the machine is working. The accuracy of alignment is related to the normal operation of the machine, especially for high-speed operation of the machine.

Accurate centering of two axes is difficult to achieve, and it is difficult to keep accurate centering for continuous running machines. Uneven thermal expansion of various parts, shaft deflection, uneven bearing wear, machine displacement and uneven foundation subsidence, etc., are the reasons for the difficulty in maintaining the shaft alignment. Therefore, in the design of the machine, there is a allowable deviation between the two axis center, which is also required when installing the coupling. From the perspective of assembly, as long as the coupling can reliably transmit torque, the greater the allowable deviation between the two axis centers, the easier it is to meet the requirements during installation. However, from the point of view of installation quality, the smaller the deviation of the center line between the two axes, the better the operation of the machine, the longer the service life. Therefore, the allowable deviation of the two shaft pairs during the coupling installation cannot be regarded as the allowance left by the installer's hasty construction.

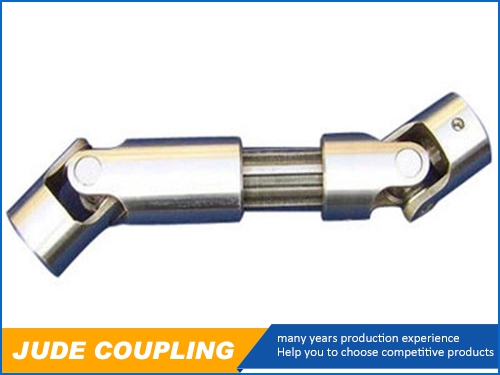

Clamp shell coupling assembly and disassembly shaft without axial movement, so very convenient installation and spherical shell coupling faults is low accuracy in the two axis, complicated structure and shape, low precision manufacturing and balance, is only applicable to low speed and load steady occasions, usually linear velocity at the outer edge of no greater than 5 m/s, when the linear velocity more than 5 m/s need for balance calibration.

The clamping shell coupling is made use of two clamping shells divided along the axial direction and clamped by bolts to realize the connection of two axes. The torque is transferred by the friction force between the surfaces of the two halves of the coupling, and the flat key is used as the auxiliary connection.

In order to improve the balance, the bolts should be installed in the upright and inverted phases. The clamped coupling has no axial, radial and angular compensation performance.

The characteristics of the vertical clamp-shell coupling are similar to that of the clamp-shell coupling, with simple structure and convenient assembly and disassembly. It is suitable for low speed (circular velocity of 5M/S), no impact and stable vibration load.

Product

Product

Internet Content Provider:冀ICP备18017241号-1

Copyright © 2019 - 2020 jude transmission All Right Reserved.