-

Product name:

-

Product description:Plum joint is a kind of coupling which is widely used, also known as claw coupling, is composed of two metal claw disc an..

-

URL:

|  |

|  |

|  |

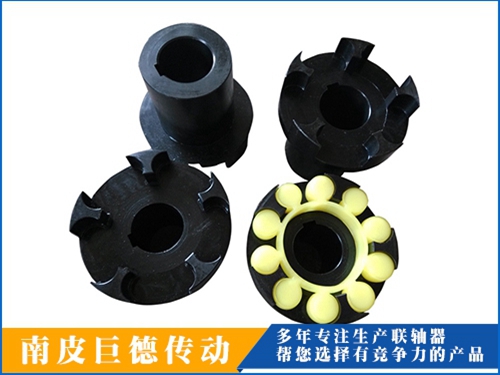

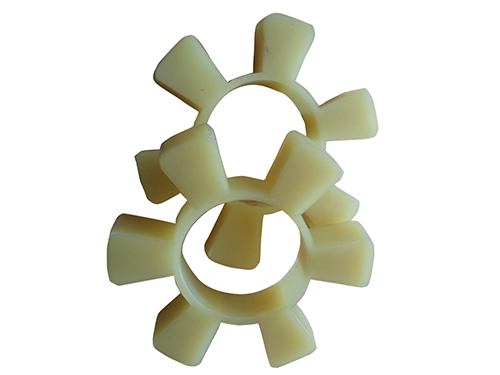

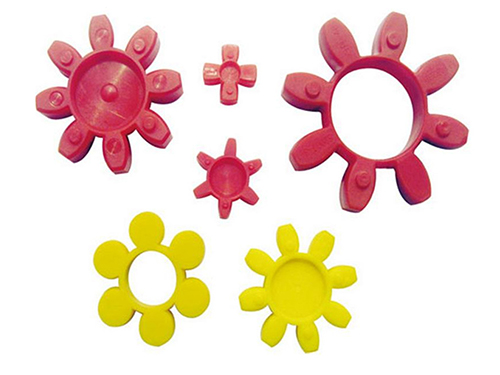

Plum joint is a kind of coupling which is widely used, also known as claw coupling, is composed of two metal claw disc and an elastic body. The two metal pawl plates are usually size 45 steel, but they are also useful for aluminum alloy under conditions requiring sensitive loading.

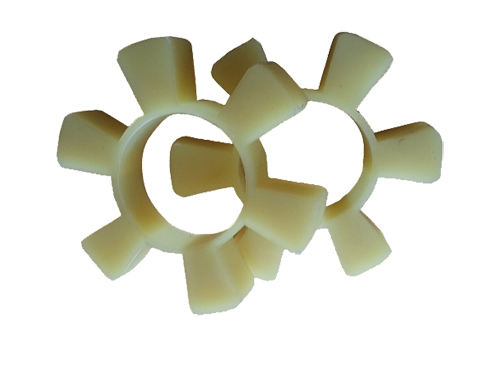

Elastomers are generally made of engineering plastics or rubber. The life of the coupling is the life of the elastomer. Because the elastomer is compressed, it is not easily pulled. Generally, the life of elastomer is 10 years. Because elastomer has the function of buffering and reducing vibration, it is often used when there is strong vibration. The performance temperature of the elastomer determines the service temperature of the coupling, which is generally -35 to +80 degrees.

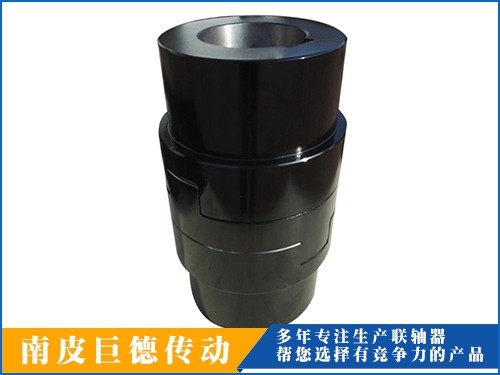

Fixed type

Set screw fixed plum coupling, also known as claw coupling, is composed of two metal claw disc and an elastomer. The two metal claws are usually size 45 steel, but can also be used in aluminum or stainless steel under conditions requiring sensitive loads. In order to connect the two halves of the coupling, the spring element of the quince-shaped shaft is placed between the protruding claws of the coupling. It has the characteristics of compensating relative displacement of two axes, reducing vibration, buffering, small radial size, simple structure, no lubrication, high bearing capacity and convenient maintenance, etc.

Professional coupling factory teacher you correct plum blossom coupling installation skills, the use of plum blossom coupling is more and more widely, but many users of the installation of some details of the plum blossom coupling is not very clear, here is a simple introduction for you:

1. Before installation, check whether the two shafts of prime mover and working machine are concentric, whether there is wrapping paper and bruise on the surface of the two shafts, whether there are sundries in the inner hole of the two halves of the plum blossom coupling, whether there is bruise on the edge of the edge of the inner hole, if there is, clean up the shaft and half coupling, and handle the bruise with a fine file. Then check whether the diameter and length of the inner hole of the two semi-couplings are consistent with the dimensions of the diameter and shaft extension length of the prime mover and the working machine. General selection, let the prime mover and working machine end half coupling length is less than the shaft extension length of 10-30mm.

2. In order to facilitate installation, the two semi-couplings are preheated in the insulation box or oil tank of 120--150, making the inner hole size increase and easy to install. After installation, ensure that the shaft head can not protrude the end face of the semi-coupling, it is better to be flush. Test the distance between the two halves of the coupling: take the average value of the readings at 3--4 points measured along the inner sides of the flange of the half coupling, and the sum of the measured sizes of the extension section and the two diaphragm groups. The error between the two is controlled within the range of 0 -- 0.4mm.

3. Alignment: use a dial indicator to detect the end face and cylindrical runout of the flange of the two halves of the coupling. When the flange's outer circle is less than 250mm, the runout value should not be greater than 0.05mm; When the flange outer circle is greater than 250mm, the runout value should not be greater than 0.08.

4. Installation bolt: put the bolt into the outer side of the small hole of the flange, and put out the upper buffer sleeve, elastic washer, and twist the nut, and tighten the nut with a wrench. If the installation is uncomfortable or disassembled or replaced, and the shaft and semi-coupling are not damaged, it is better to rotate freely after the installation.

5. Operators should check whether the nuts of the plum blossom coupling are loose or fall off before starting the equipment. If so, tighten the nuts with a wrench in time.

The shaft coupling is processed by turning, milling, broaching and other machining methods, and then through the overall heat treatment. In order to ensure sufficient mechanical strength, there is also a kind of claw disc casting on the market, which can be produced in large quantities without processing loss. Therefore, the price is much lower than that of machining. However, the casting performance is not very good. Don't use zui in important situations. Moreover, the jaw teeth of the casting are prone to tooth beating (tooth loss) under the condition of high speed or high load.

Plum coupling features:

1. Compact type, no tooth gap, provides three kinds of elastomers with different hardness;

2. Maintenance-free, oil resistant and electrical insulation, operating temperature 20℃-60℃;

3. Fixed way: top wire, clamping, keyway fixing.

4. Can absorb vibration and compensate radial and angular deviation;

5. The club elastomer has four, six, eight and ten petals;

6. Simple structure, convenient maintenance and inspection;

江苏Coupling elastic spider/rubber 上海Coupling elastic spider/rubber

News

News

Internet Content Provider:冀ICP备18017241号-1

Copyright © 2019 - 2020 jude transmission All Right Reserved.