-

Product name:

-

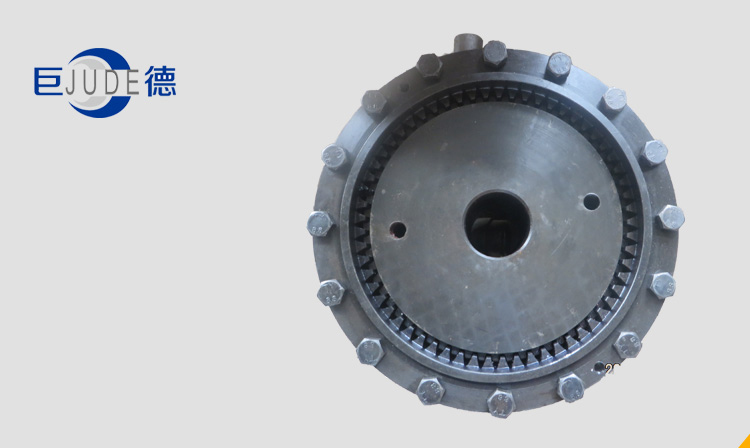

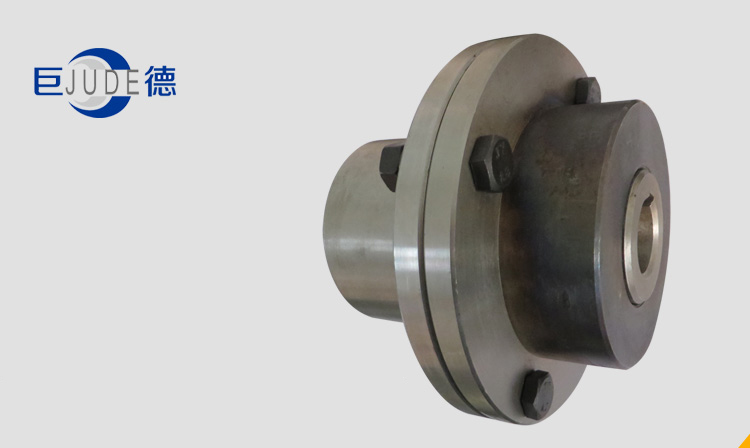

Product description:Compared with CL type straight gear coupling, drum type gear coupling has the advantages of compact structure...

-

URL:

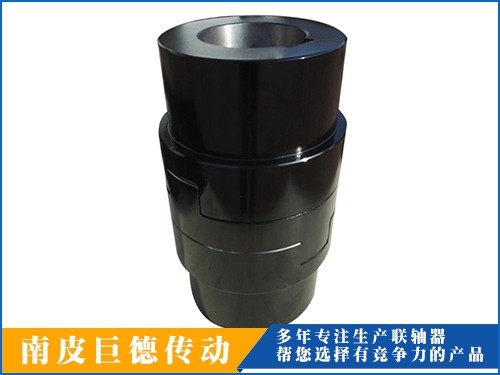

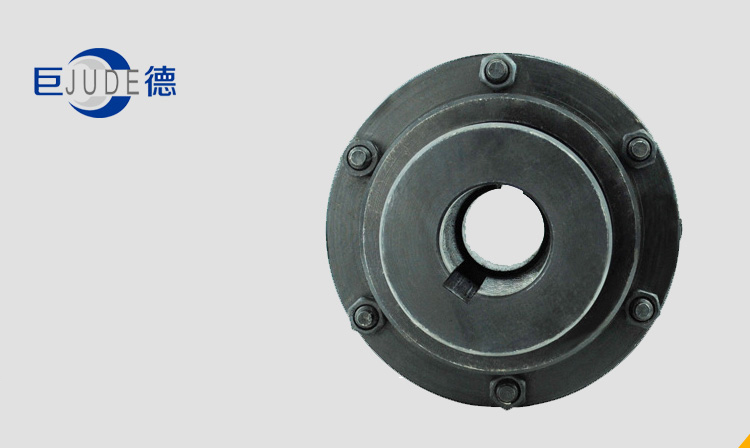

Compared with CL type straight gear coupling, drum type gear coupling has the advantages of compact structure, small turning radius, large bearing capacity, high transmission efficiency, low noise and long maintenance cycle.

Features of drum type coupling (compared with straight type coupling, it has the following features) :

1. Strong carrying capacity. Under the same outer diameter of inner sleeve and outer diameter of coupling, the carrying capacity of drum type coupling is 15 ~ 20% higher than that of straight type coupling on average.

2. Large angular displacement compensation. When the radial displacement is equal to zero, the allowable angular displacement of the straight-tooth coupling is 1º , while the allowable angular displacement of the drum gear coupling is 1º 30 ", increase by 50%, under the same modulus, the number of teeth, the width of the teeth, drum teeth than the allowable angular displacement of straight teeth;

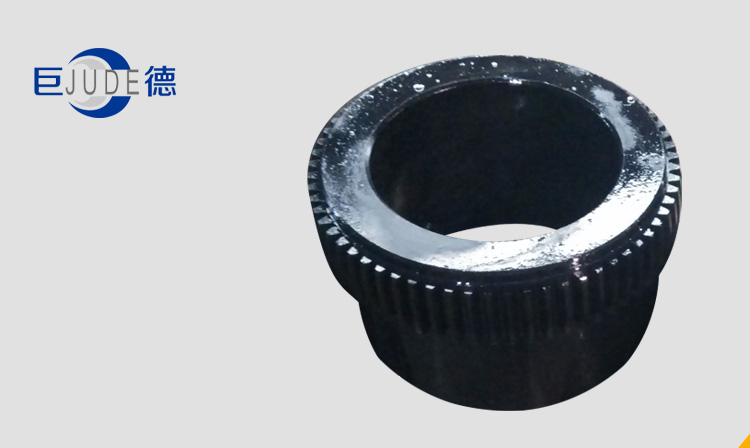

3. The drum tooth surface improves the contact conditions of the inner and outer teeth, avoids the disadvantages of edge extrusion and stress concentration at the end of the straight tooth under the condition of angular displacement, improves the friction and wear condition of the tooth surface, reduces the noise, and leads to long maintenance cycle;

4, the tooth end of the outer tooth sleeve is shaped like a horn, which makes it very convenient to assemble and disassemble the inner and outer teeth.

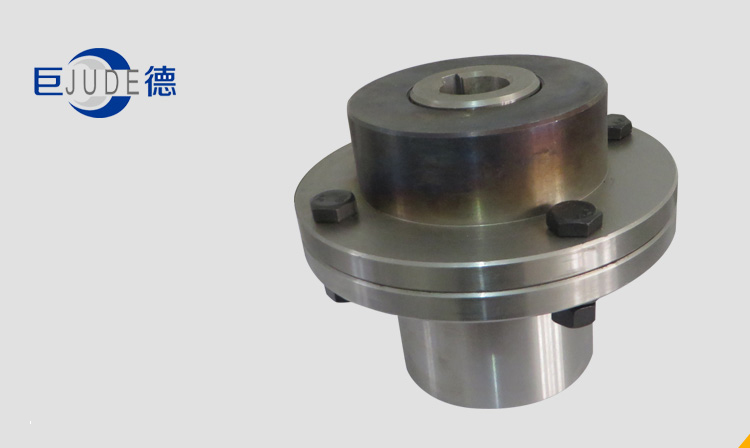

5. Transmission efficiency is up to 99.7%. Based on the above characteristics, drum gear has been widely used to replace the straight gear coupling at home and abroad. The drum type gear coupling, its rigidity is big, has the flexibility, inelastic, therefore is not suitable for the request to reduce the vibration, the buffer and the two axis in the request strictly mechanical.

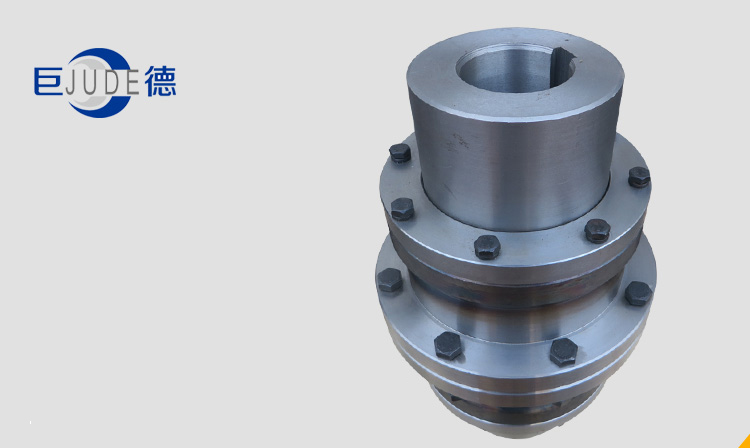

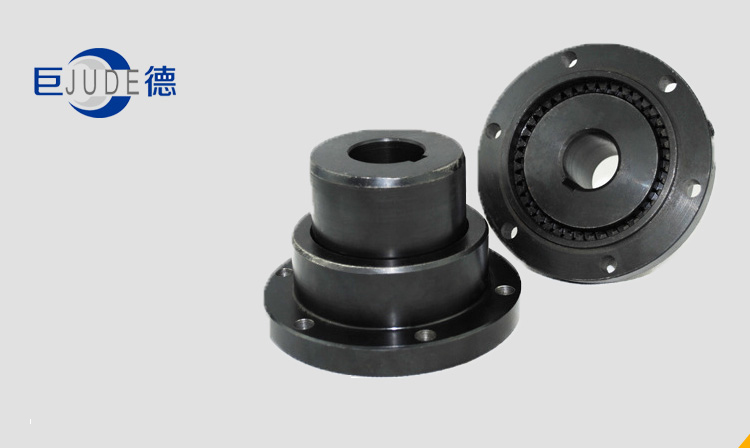

A strong ability to absorb connection errors

In a wide variety of couplings, the drum gear couplings have the advantages of small size, large transmission torque, strong ability to absorb connection error, and excellent durability. In engineering practice, due to manufacturing and installation errors, deformation, wear, foundation subsidence and other reasons, will cause the two axis axis of the deviation, axial displacement, radial displacement, angular displacement and comprehensive displacement. The existence of offset makes the shaft, bearing and coupling produce additional dynamic load, which causes vibration and worsens the working condition of machine parts.

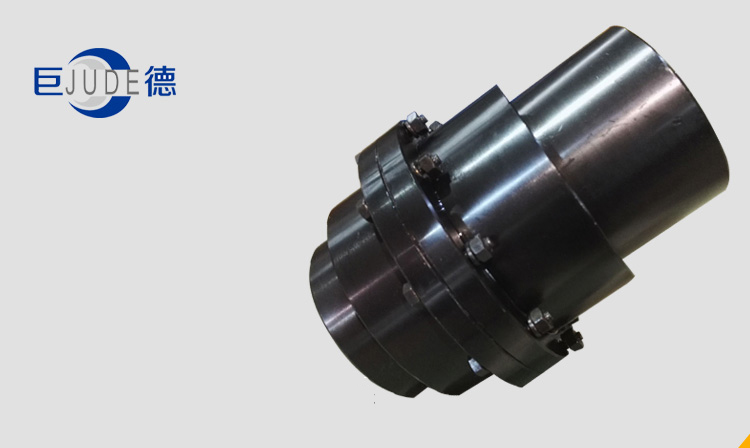

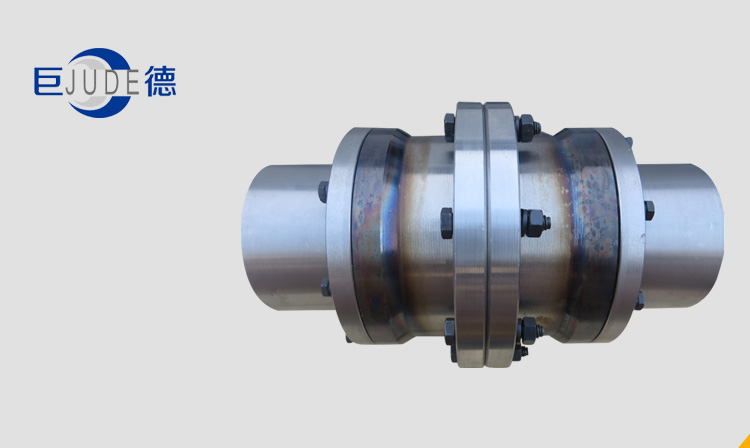

With the development of modern industrial technology, more and more high requirements have been put forward for the technical and economic indexes such as bearing capacity, reliability, efficiency, circular velocity, volume and weight of the drum gear coupling. Drum type coupling is developed on the basis of straight type coupling to meet the requirements of large inclination Angle, variable inclination Angle, small size and high reliability and other technologies. The structure of the drum - tooth coupling is basically symmetrical. From the direction of the top of the outer tooth shaft sleeve teeth for drum teeth, tooth thickness from the center to both sides gradually reduce, and it meshes with the inner ring teeth for straight teeth. Since the top and face of the outer tooth sleeve are curved, the whole coupling is double-jointed and flexible, so that the larger deflection Angle between the two axes can be adapted. Drum gear coupling plays an important role in production practice. It can compensate the angular error, axial and radial installation error caused by misalignment of the two connecting axes, and allow a certain displacement of the two axes.

Research on the background of the drum gear coupling, the coupling is an important mechanical foundation components, its function is to drive shaft and driven shaft together, transfer torque to make the two axis rotation. Under special working conditions, such as the drum tooth coupling used in glass industrial mixer, because the stress state of the drum tooth is a multi-tooth contact, nonlinear problem, there is a large deviation between the traditional calculation model and the actual engineering, tooth surface fatigue damage and connection bolt hole deformation and other failure problems are still urgent to study and solve the problem.

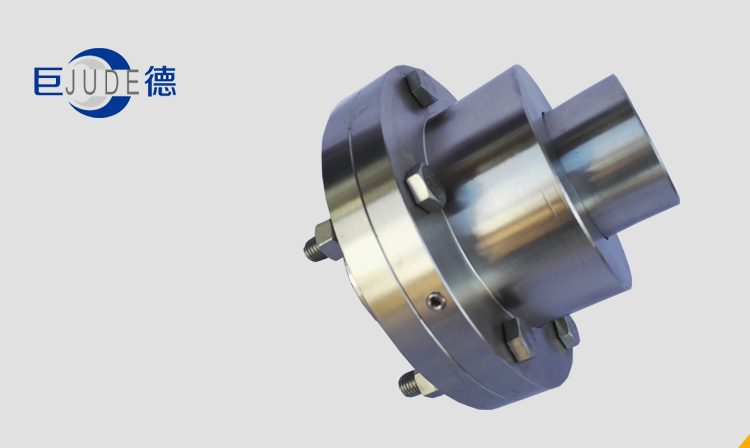

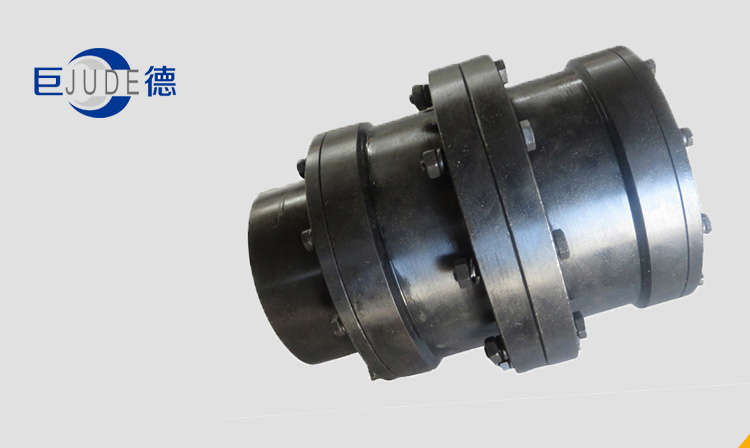

GICL, GIICL series of drum gear coupling, especially suitable for low speed and heavy load conditions, such as metallurgy, mining, lifting and transportation industries, also suitable for petroleum, chemical, general machinery and other types of machinery shaft drive.

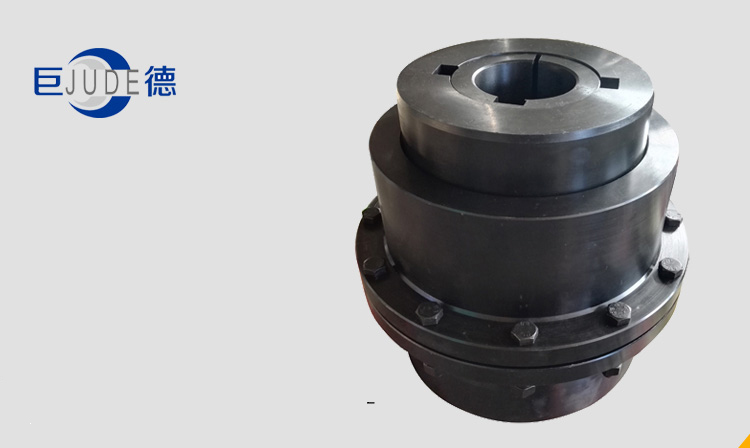

The main advantages of WG type drum gear coupling are as follows: after carburizing and quenching the tooth surface of drum gear engagement, the bearing capacity is high; The main failure form of drum tooth is wear. After forced lubricating with thin oil, the wear of tooth surface is greatly reduced, and the wear amount is about 10% of grease lubrication. The circulating thin oil can take away the rolling heat of roller end and the heat generated by gear tooth friction, effectively preventing the allowable contact stress on the material surface of gear tooth from reducing. Under normal circumstances, there will be no broken teeth, to meet the requirements of continuous rolling mill characteristics; The drum type gear coupling can meet the rolling requirements of the rolling mill, stretching is very convenient; Use, cleanliness, etc.

The contact condition of the tooth can be improved

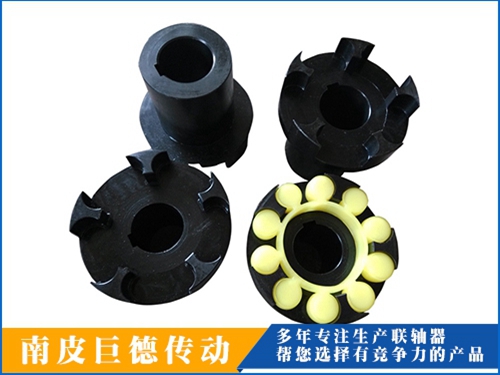

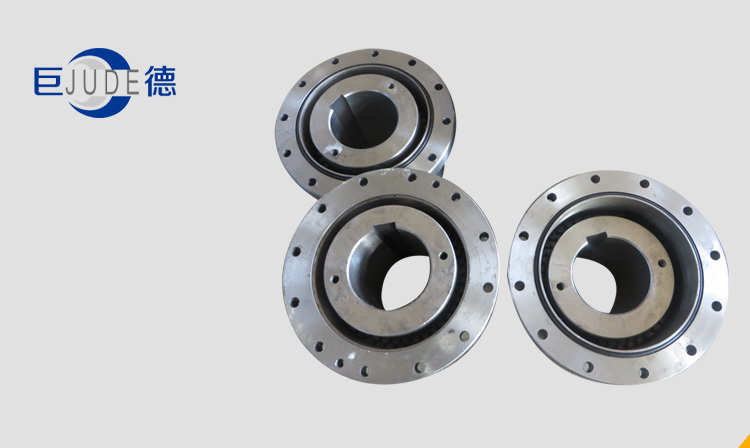

The outer teeth of the drum type coupling are divided into straight teeth and drum teeth. The drum type coupling can allow a large angular displacement (relative to the straight tooth coupling), which can improve the contact conditions of the teeth, improve the ability to transfer torque, and extend the service life. The contact state along the tooth width when angular displacement is present.

The drum gear coupling has the advantages of compact structure, small turning radius, large bearing capacity, high transmission efficiency, low noise and long maintenance cycle etc. The drum type gear type coupling is in the work, therefore, the gear type coupling must have the good and under the seal condition work.

Gear coupling radial size is small, bearing capacity is large, often used in low speed and heavy load conditions of the shaft drive, high precision and dynamic balance of the gear coupling can be used for high speed drive, such as gas turbine shaft drive. Because the angular compensation of the drum type coupling is larger than that of the straight type, the ling drum type coupling is widely used at home and abroad. The drum type gear type coupling belongs to the rigid flexible coupling. This product has complete specifications. And to undertake all kinds of non-standard support design and manufacture, good quality, stable use, abide by the contract, timely delivery, reasonable price, the implementation of three guarantees, agent transport.

江苏Drum type gear coupling 上海Drum type gear coupling

News

News

Internet Content Provider:冀ICP备18017241号-1

Copyright © 2019 - 2020 jude transmission All Right Reserved.