-

Product name:

-

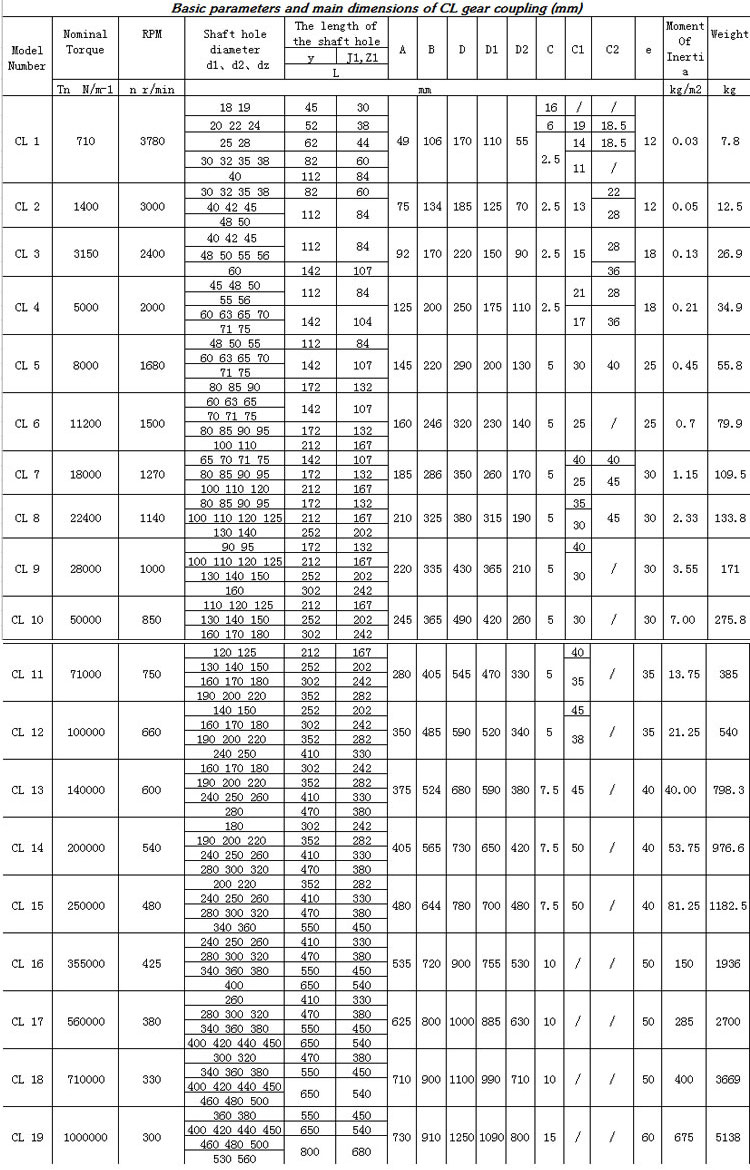

Product description:CL type gear coupling belongs to rigid coupling, which is composed of inner gear ring with same number of teeth and flang..

-

URL:

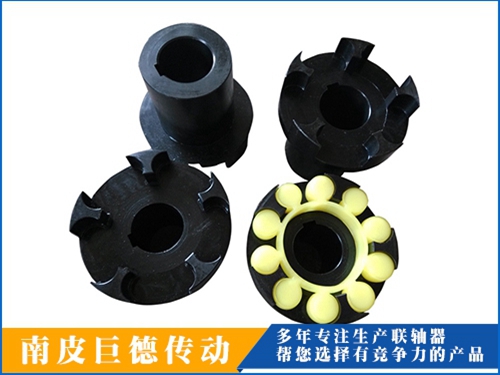

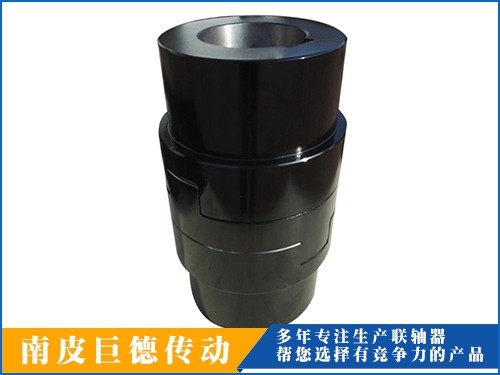

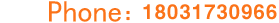

CL type gear coupling belongs to rigid coupling, which is composed of inner gear ring with same number of teeth and flange half coupling with outer teeth. Divided into straight teeth and drum tooth outside two kinds of tooth shape, tooth is the so-called drum will made spherical outer teeth, spherical center on the gear axis, backlash is generally large gear, drum gear couplings allows a larger angular displacement (as opposed to ordinary type coupling), can improve the tooth contact conditions, improve the ability to transfer torque, prolong service life.

Contact state along the tooth width when CL type gear coupling has angular displacement. Radial, axial and angular axis deviation compensation ability, has a compact structure, small turning radius, large carrying capacity, high transmission efficiency, low noise and long maintenance cycle, especially suitable for the condition of low speed and heavy loading, such as metallurgy, mining, lifting transportation and other industries, can also be applied to petroleum, chemical industry, general machinery and other kinds of shaft transmission of machine

When the CL type gear coupling is in operation, relative angular displacement is generated between the two axes, and the tooth surfaces of the inner and outer teeth are subject to relative axial sliding periodically, which will inevitably lead to tooth surface wear and power consumption. Therefore, the CL type gear coupling should work in a good and sealed state. CL type gear coupling, with small radial size and large bearing capacity, is often used for shafting transmission under low-speed and heavy-load working conditions. Gear coupling with high accuracy and dynamic balance can be used for high-speed transmission, such as shaft transmission of gas turbine.

Features of CL type gear coupling

1. Strong carrying capacity. Under the same outer diameter of inner sleeve and outer diameter of coupling, the carrying capacity of drum type coupling is 15 ~ 20% higher than that of straight type coupling on average.

2. Large angular displacement compensation. When the radial displacement is equal to zero, the allowable angular displacement of the straight type coupling is 1o, while the allowable angular displacement of the drum type coupling is 1o30', increasing by 50%. With the same modulus, tooth number and tooth width, the allowable angular displacement of drum tooth is larger than that of straight tooth.

3. The drum tooth surface improves the contact conditions of the inner and outer teeth, avoids the disadvantages of edge extrusion and stress concentration at the end of the straight tooth under the condition of angular displacement, improves the friction and wear condition of the tooth surface, reduces the noise, and leads to long maintenance cycle;

4. The end of the outer tooth sleeve is shaped like a horn, which makes it convenient to assemble and disassemble the inner and outer teeth;

5. Transmission efficiency is up to 99.7%;

江苏CL gear coupling 上海CL gear coupling

- prev:CLZ type gear coupling

- next:GCLD gear coupling

News

News

Internet Content Provider:冀ICP备18017241号-1

Copyright © 2019 - 2020 jude transmission All Right Reserved.